|

Overview

900 Type Diesel Cranking

Motors Bosch Magneto

Project Carbon Pile

Regulator Machined

Aircraft Parts

Non-Ferrous Foundry

Propeller Shifter Switch

Radio Shielding Project

Sperry Servo Units

Supercharging Blowers

World War

Two Product Documents

Supercharging Blowers

This page updated

12-4-2020.

The supercharger blower described in the document below was one of four products that

were supplied to the Detroit Diesel Division of General Motors for use

on its 6-71 six-cylinder 225hp diesel engine. The other three

Delco-Remy products on the 6-71 were the starter, DC generator and

voltage regulator. The 6-71 was the workhorse small diesel engine

of World War Two and was used extensively on armored vehicles and

various landing craft during World War Two. The Delco-Remy super

charging blower was a high precision product that was instrumental

part in keeping American armored vehicles and landing craft

operating at top efficiency.

Plant 7, with the

assistance of the Antioch Foundry in Yellow Springs, OH, were responsible

for the cost effective casting of the two blowers that went into each

supercharger. Interestingly enough, the Muncie Battery Plant was

the point of final assembly of the blowers into the case and end pieces.

As of July 1943, Delco-Remy was delivering 6,500 blowers per month to Detroit

Diesel.

The next two tables show

the variety of armor and landing craft in which the Delco-Remy supercharger

blower was used. These numbers also apply to starters, DC

generators and voltage regulators. From the data below, a minimum

of 95,551 blowers were required for OEM shipments during World War Two.

|

Detroit Diesel

Engine World War Two Tank Applications |

|

Armored Vehicle |

Number

built |

Type

Engine |

Engines per tank |

Total

Engines |

6-71

Engines per tank |

Total

6-71 Engines |

Total Blowers Required |

Comments |

|

British and Canadian Valentine |

3,981 |

6-71

|

1 |

3,981 |

1 |

3,981 |

3,981 |

|

|

British Valentine SP Anti-Tank with 17 pounder main gun |

665 |

6-71 |

1 |

665 |

1 |

665 |

665 |

|

| M3

Grant/Lee |

913 |

6046 |

1 |

913 |

2 |

1,826 |

1,826 |

The

6046 was two 6-71 engine blocks working together as one power

plant. |

| M4A2

Sherman Tank |

10,968 |

6046 |

1 |

10,968 |

2 |

21,936 |

21,936 |

This

was about 20% of the total M4 Sherman production in WWII.

The US Army preferred gasoline powered tanks, since

that was the fuel it normally used in its vehicles. The

Detroit Diesel powered M4A2 Shermans served either with the USMC,

which had access to US Navy diesel fuel, or were sent overseas as

part of Lend Lease. |

| M10

Tank Destroyer |

4,993 |

6046 |

1 |

4,993 |

2 |

9,986 |

9,986 |

The

M10 Tank Destroyer was a US Automobile Industry product being

built by the GM Fisher Body Division at Grand Blanc, MI. |

|

Totals |

21,520 |

|

|

21,520 |

|

38,392 |

38,392 |

This

does not include any spares. |

|

Detroit Diesel

Engine World War Two Landing Craft Applications |

| Type

Landing Craft |

Number

built |

Type

Engine |

Engines per Landing Craft |

Landing Craft using Detroit Diesel Engines for propulsion |

Number

of Detroit Diesel Engines for propulsion |

Number

of 6-71 for ship's power |

6-71

Engines Usage |

Total Blowers Required |

2-71 Engine Usage |

Comments |

| LCP(L) |

2,193 |

Various including

Gray Marine 64HN9/Detroit Diesel 6-71 |

1 |

1,097 |

1,097 |

|

1,097 |

1,097 |

|

Assumes 50% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCP(R) |

2,572 |

Various including

Gray Marine 64HN9/Detroit Diesel 6-71 |

1 |

1,286 |

1,286 |

|

1,286

|

1,286

|

|

Assumes 50% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCV |

2,366 |

Various including

Gray Marine 64HN9/Detroit Diesel 6-71 |

1 |

1,183 |

1,183 |

|

1,183

|

1,183

|

|

Assumes 50% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCVP |

23,353 |

Gray Marine

64HN9/Detroit Diesel 6-71 or Hudson built Hall-Scott 210 hp

gasoline powered Invader |

1 |

19,353 |

19,353 |

|

19,353 |

19,353 |

|

Some LCVPs received the Hudson built-Hall-Scott 210 hp gasoline

powered Invader engines due to the fact Detroit Diesel could not

supply all of the engines the military was requesting.

Hudson built 4,000 of these, so I have used that number to

subtract from 23,353. |

| LCM(3) |

8,631 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

4,223 |

8,446 |

|

8,446 |

8,446 |

|

Assumes 50% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCM(4) |

2,718 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

2,039 |

4,078 |

|

4,078 |

4,078 |

|

Assumes 75% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCM(6) |

2513 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

1,885 |

3,770 |

|

3,770 |

3,770 |

|

Assumes 75% Gray

Marine 64HN9/Detroit Diesel 6-71, as that was the preferred

engine. |

| LCT(5) |

470 |

Gray Marine 64HN9/Detroit Diesel 6-71 |

3 |

470 |

1,410 |

|

1,410 |

1,410 |

|

|

| LCT(6)

|

960 |

Gray Marine

64HN9/Detroit Diesel 6-71 |

3 |

960 |

2,880 |

|

2,880 |

2,880 |

|

|

| LCI(L) |

923 |

Detroit Quad

Diesels (6051) |

2 |

923 |

1,846 |

1,846 |

9,230 |

9,230 |

1,846 |

The 6051 was the

designation for four 6-71s tied together. The ship's power

on the LCI was provided by two 2-71 engines driving 20KW

generators. |

| LCS(L) |

130 |

Detroit Quad

Diesels (6051) |

2 |

130 |

260 |

260 |

1,300 |

1,300 |

260 |

The ship's power

on the LCS(L) was provided by two 2-71 engines driving 20KW

generators. There is still one LCS(L) in existence at Mare

Island in San Francisco, CA. See the links page for more

information. |

| LST |

1,052 |

Detroit Diesel

6-71 |

3 |

1,052 |

0 |

3,156 |

3,156 |

3,156 |

|

The ship/s power

on the LST was provided by three 6-71 engines driving 100KW

generators. |

| Totals |

47,881 |

|

|

34,601 |

45,609 |

5,316 |

57,189 |

57,189 |

2,106 |

This

does not include any spares. Also, this is almost a year's

production for Detroit Diesel during the WWII. |

| Type

Landing Craft |

Number

built |

Type

Engine |

Engines per Landing Craft |

Landing Craft using Detroit Diesel Engines |

Number

of Detroit Diesel Engines |

Number

of 6-71 for ship's power |

6-71

Engines Usage |

Total Blowers Required |

2-71

Engines Usage |

Comments |

The engineering report

below reveals that Delco-Remy was not only casting the rotors, but then

assembling them into the final blower unit. The assembly operation

was in the Muncie battery plant and as of July 1943, Delco-Remy was

delivering 6,500 blowers per month to the Detroit Diesel Division of

General Motors. 6,500 units per month may be a misprint as Detroit

Diesel built an estimated 95,000 6-71 engines during World War Two.

This production of 95,000 engines took place from 1941 to 1945. As

popular as the 6-71 was during the war, Detroit Diesel had a difficult

time keeping up with demand. If Delco-Remy was producing 6,500

units a month in July 1943, after a year it would have produced 78,000

blowers. It would be building more blowers than Detroit Diesel

could use. This would have been wasted production capacity for

Delco-Remy. D-R was also strapped to meet production during the war.

All companies were. It could have used the this capacity for other

products needed by the military. 650 units per month would be more

reasonable. Delco-Remy production started in late 1941 or early

1942 on the blowers. Maybe the 6,500 units was total production

over that time period. We will never know. It should be

noted that from the "Supercharging Blowers" engineering report that D-R

was not the only manufacturer of the blower. It was the largest,

but there was other unit being made by other companies to provide

Detroit Diesel with enough blowers to keep production running.

In spite of what the

question on how many were being produced, this was still a significant

product that Delco-Remy made for the winning of World War Two, as there

was a blower on each 6-71 diesel engine it built. These were used

in Sherman tanks, Wolverine tank destroyers and most of the landing

craft during the war. It is hard to understand why there was not

more emphasis on this product in "Our War Job" or the February 5, 1945

issue of the Clan. One reason the final assembly of the blowers is

overlooked is that the final assembly was in Muncie, and the both 'Our

War Job" and the Clan are Anderson centric. There is no mention on

the number of batteries in the Clan that the Muncie battery plant

provided for the war effort.

It is noted in the

document that Delco-Remy was the largest supplier of the supercharging

blowers to Detroit Diesel.

The document in this section is courtesy of the Madison County Historical Society in

Anderson, IN.

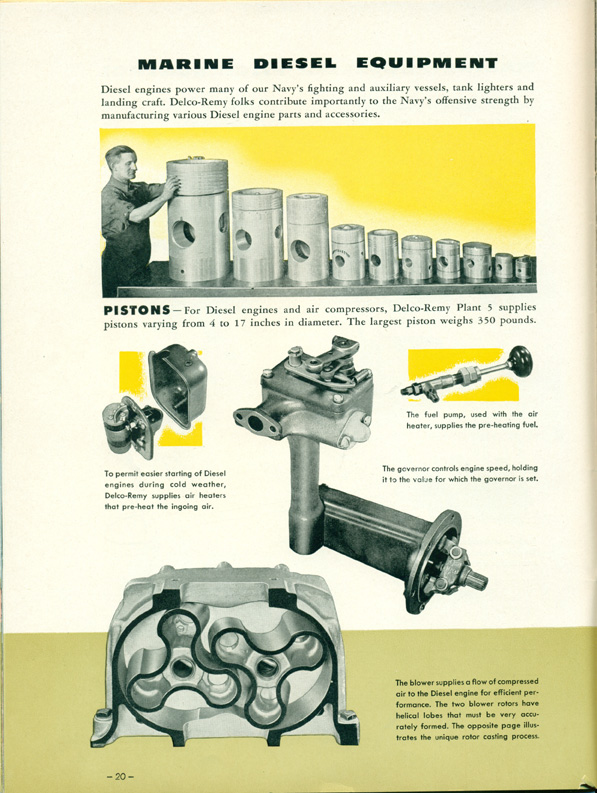

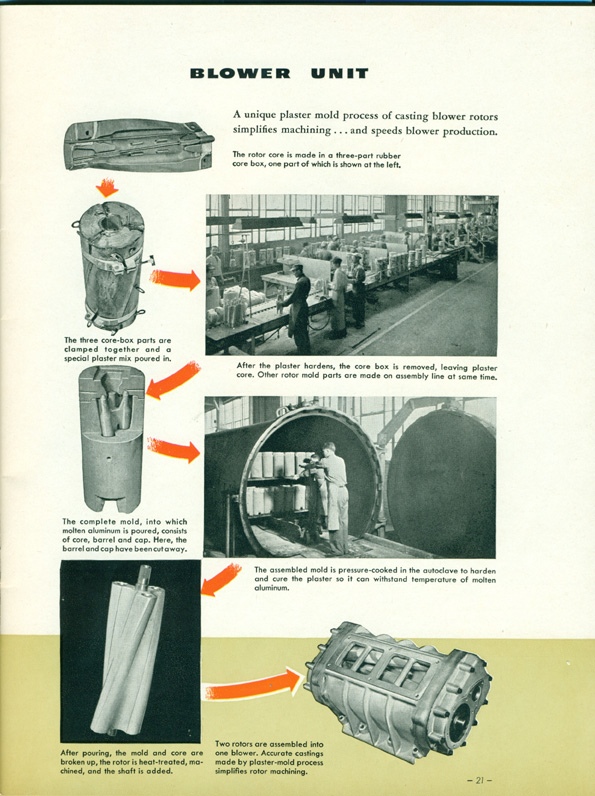

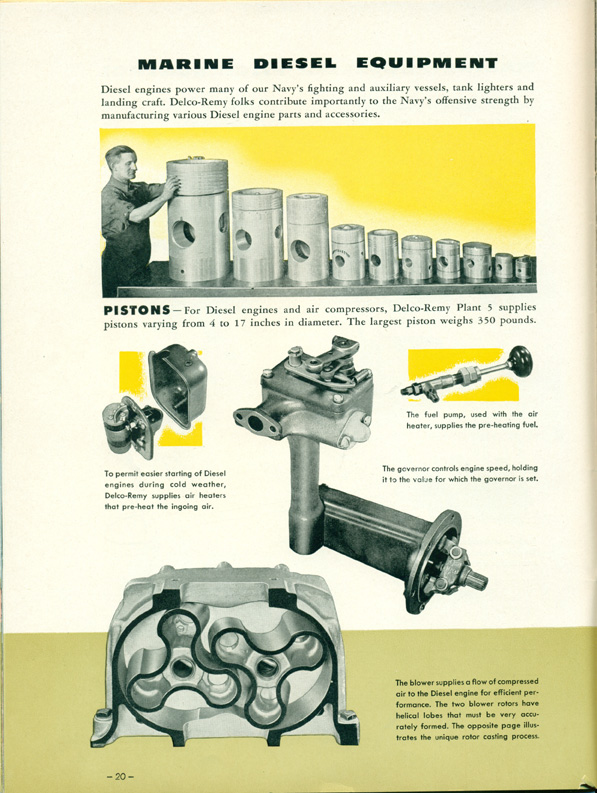

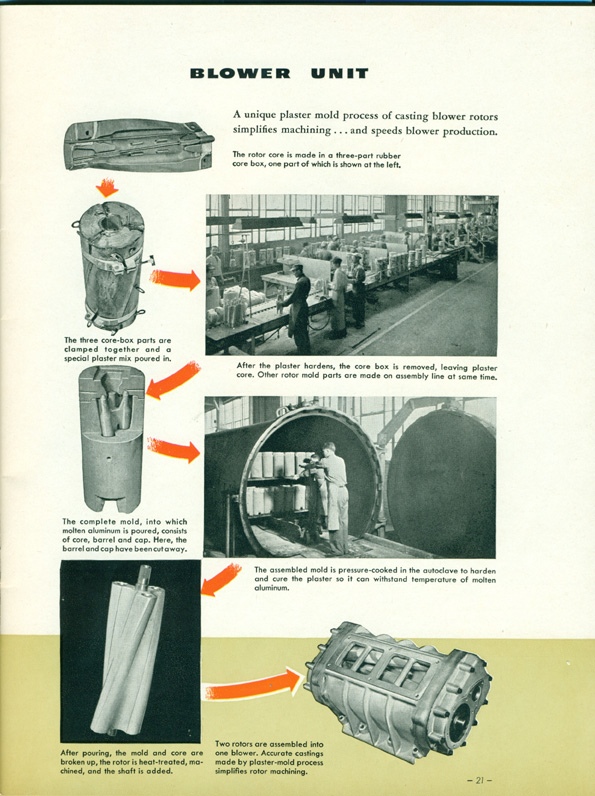

From "Our War Job."

From "Our War Job."

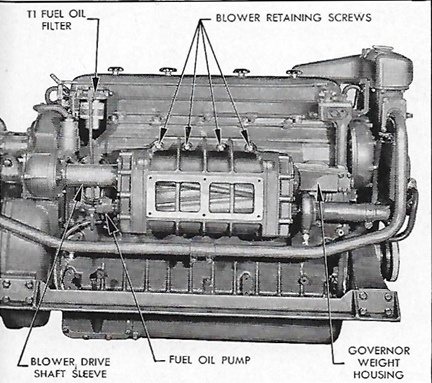

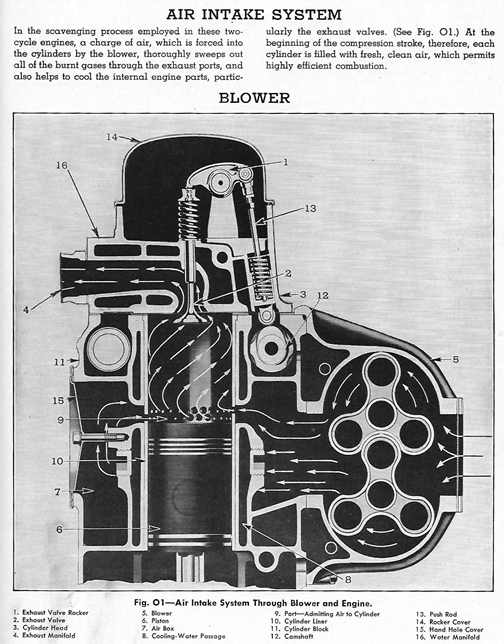

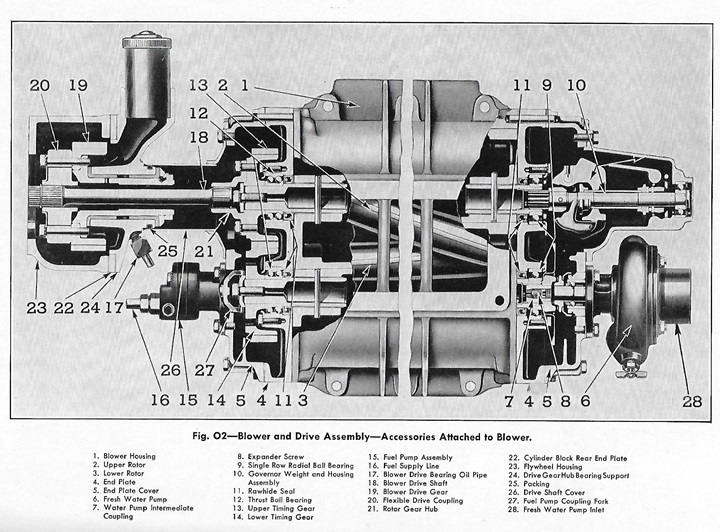

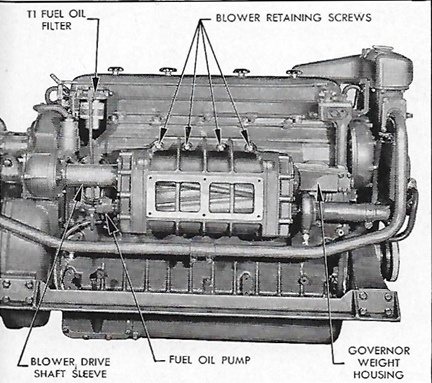

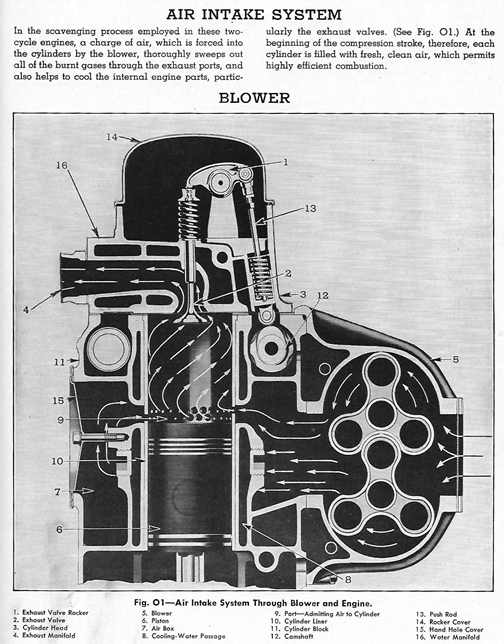

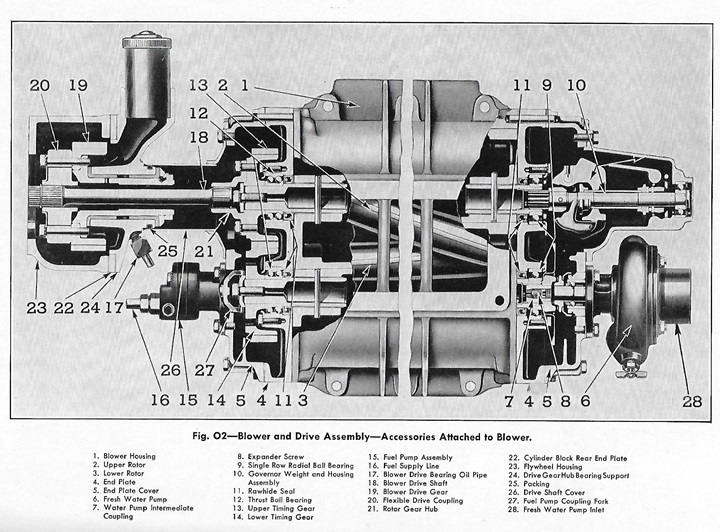

This and the following images are from a

Gray Marine student manual used to train sailors, coastguardsmen and

soldiers on how to maintain a Gray 64HN9 marine engine which was the

main engine used on most of the 34-foot wooden landing craft of World

War Two. It was the main engine used on these landing craft which

included the Higgins boat. The Gray 64HN9 was a Detroit Diesel

6-71 engine that was modified for marine operation. The 64HN9 also

had a Delco-Remy starter, generator and voltage regulator installed on

it.

Yes, soldiers operated

landing craft. The U.S. Army had its own fleet of landing craft

that it operated during World War Two. The U.S. Coastguard

provided most of the crews that manned and operated the U.S. Navy's

small landing craft during World War Two.

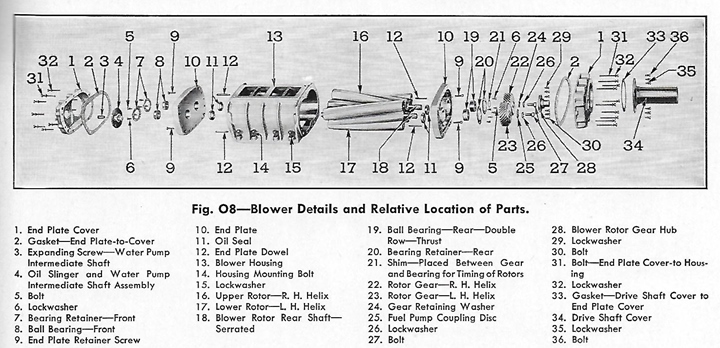

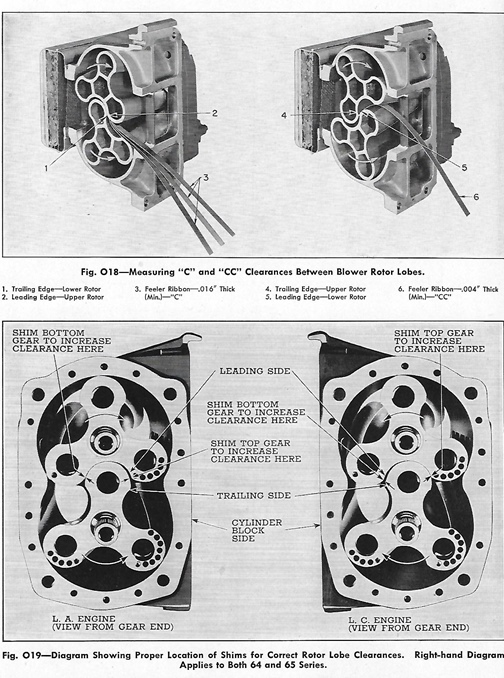

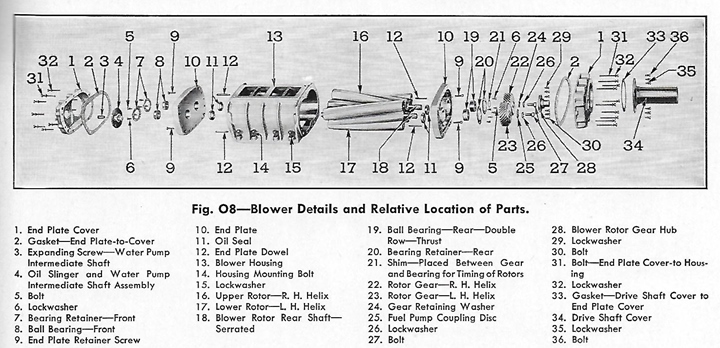

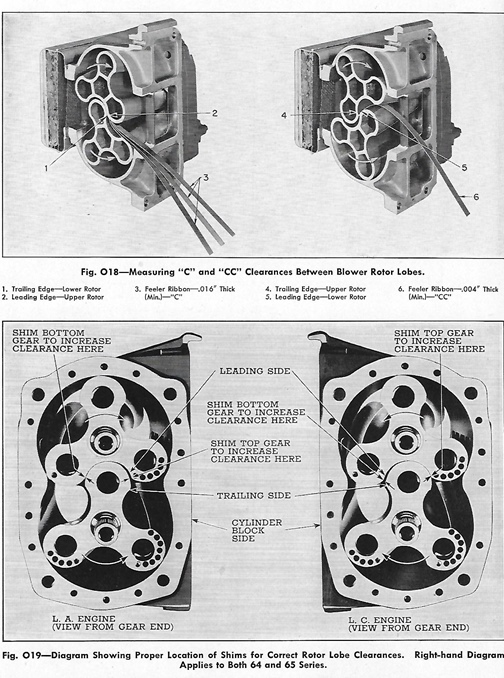

There were 36 different parts that had to be

assembled into the final unit.

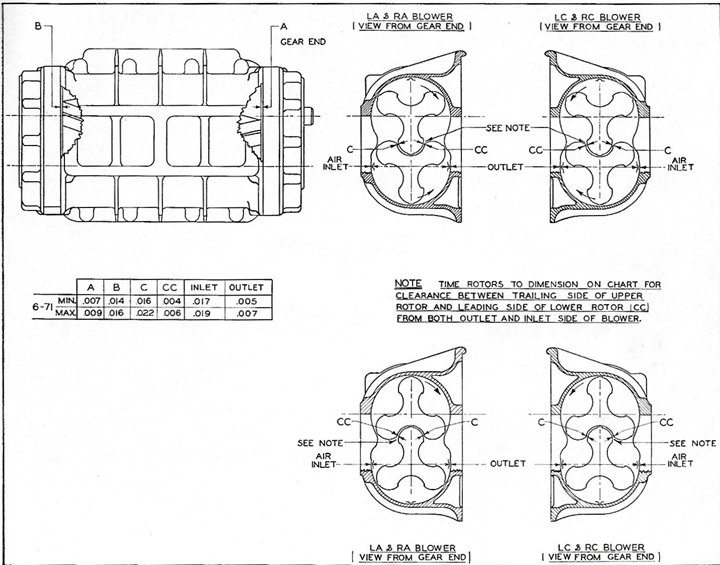

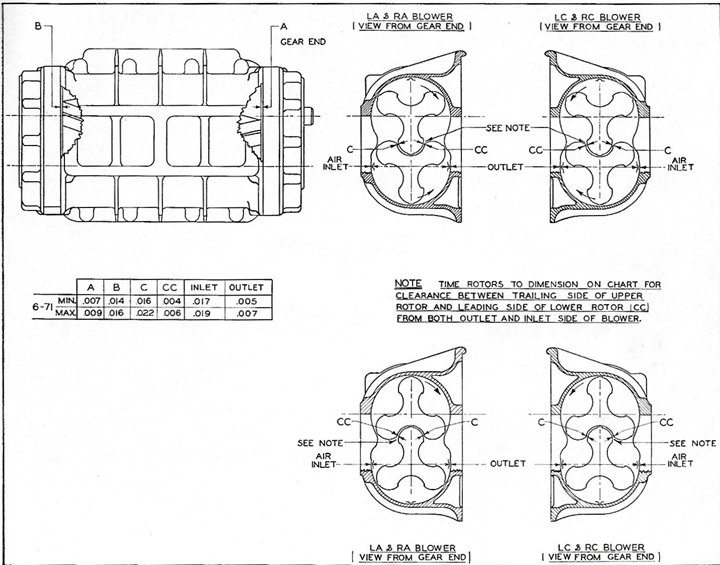

The tolerances of the rotors was critical

for the proper operation of the blower.

An M4A2 Sherman tank with a Delco-Remy blower on each of the two 6-71

engines in the tank. Photo courtesy of David Jackson, Jr.

This is a cut-away of an M4A2 Sherman tank on

display at the Canadian War Museum in Ottawa, ONT. Author's photo.

This is a cut-away of the Detroit Diesel

6046 engine which is two 6-71s married together. Author's photo.

This cut-away is unique in that it shows the

Plant 7 cast internal rotors inside the assembled super charger blower

assembled by Delco-Remy. Author's photo.

This Detroit Diesel 6-71 tank engine is on

display at the Ontario Regiment Museum in Oshawa, Ontario. The

Delco-Remy starter and solenoid can be seen in this photo.

Author's photo added 12-4-2020.

Of more interest is this view into the

output end of the blower. This shows some of the machined parts

that were part of the unit. Author's photo added 12-4-2020.

The Fisher Body Tank Arsenal in Grand Blanc,

MI built 5,368 M10

Wolverine tank destroyers with the Detroit Diesel 6046 engine. The

M10 required 10,736 blowers.

Author's photo from the Patton Museum.

This is one of 3,981 Valentine tanks built in both Canada and Great

Britain that used a Detroit Diesel 6-71 engine. Author's

Photo from the Canadian War Museum.

The Landing Craft, Vehicle, Personnel (LVCP)

Author's photo.

The supercharger blower on the 6-71

engine can be seen in the photo. Author's photo.

Delco-Remy built-blowers were used on the

Detroit Diesel engines that supplied ship's power to many of the LSTs

built during the war. Author's photo.

Here is one of the three 6-71 ship's power

engines on LST-325 in Evansville, IN. Part of the tank level deck

has been cut open so visitors can look down to see the engines inside

the auxiliary engine room. The hole is covered with Plexiglas for

safety reasons, but also impairs clear photos the engines. The

orientation is looking towards the front of the ship. The blower

is underneath the two air cleaners. Author's photo.

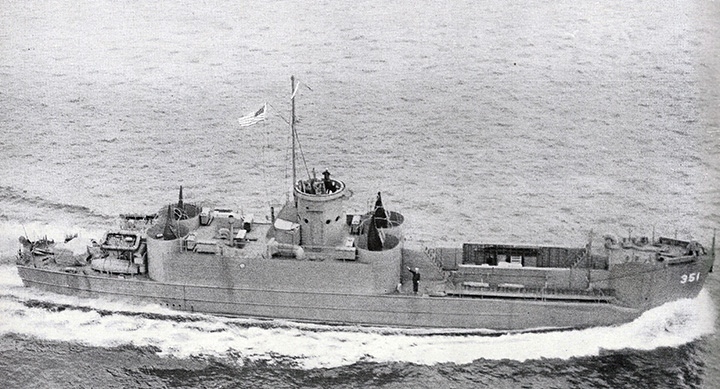

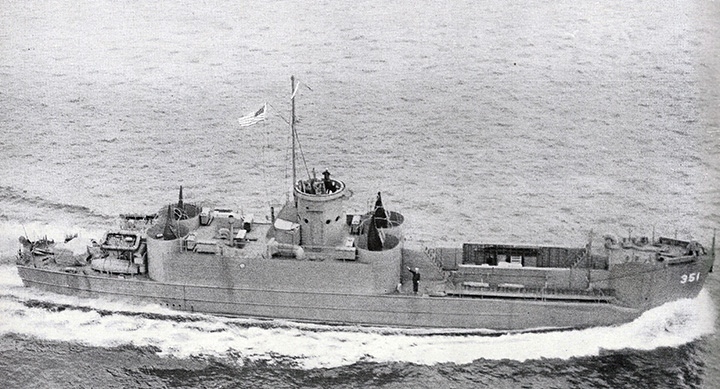

A US Navy LCI(L) (Landing Ship, Infantry

(Large)) underway during WWII with Delco-Remy equipped supercharger

blowers.

The Landing Craft, Tank was powered by three

Detroit Diesel engines equipped with Delco-Remy blowers.

This Landing Craft, Personnel (Large)

(LCP(L)) built by Higgins Industries of New Orleans, LA is on display at the

National World War Two Museum, also in New Orleans. Many of the LCP(L)s were powered by 6-71 engines with their Delco-Remy supercharger

blowers. Author's photo.

Related information can be found on the

Antioch Foundry

Page.

|