|

Delco-Remy Non-Ferrous Foundry World War Two Timeline |

| Date |

Action |

Comments |

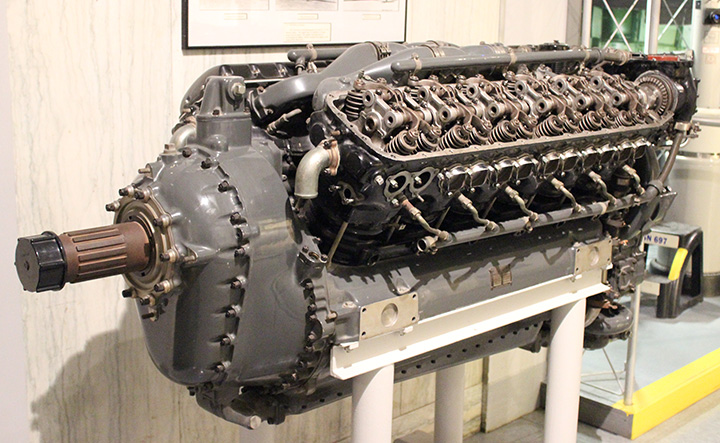

| 8-1940 |

Delco-Remy announced it would build an aluminum

foundry in Anderson. This would become the last Plant 7. |

|

| 10-10-1940 |

First

seven supervisors named for the new plant. |

|

| 12-10-1940 |

Plant 7 dedicated. |

A.G.

Glaser from Muncie was the contractor. His employees

worked 24 hours a day in September and October, 1940 in order to

build the plant in just over three months. |

| Unknown

dates |

The

seven supervisors spent three weeks at the Aluminum Company of

America (Alcoa) in Cleveland, OH which was was already casting

parts for Allison. Allison had it make a duplicate set of

molds for Delco-Remy. |

|

|

2-1-1941 |

Scheduled date for first production. This date was not met

due to late engineering changes. |

|

|

3-10-1941 |

First

part cast. This was the gear case cover. |

|

|

3-12-1941 |

Sample submitted to Allison for approval. |

Both

Allison and Cadillac approved this part. Cadillac was

building the gear reducer for Allison. |

|

9-1-1941 |

All

patterns had been received. |

|

|

Unknown dates |

A

magnesium foundry was installed that used part of the plant. |

|

|

11-16-1941 |

First

magnesium samples produced. |

|

|

2-1-1942 |

Magnesium foundry converted to aluminum to provide the necessary

capacity for castings to Allison. |

The

original foundry ran large parts, and the new one ran medium and

small parts. |

|

8-1942 |

One

million pounds of castings shipped in 18 months. |

Delco-Remy provided 50% of Allison's castings. |