|

Delco-Remy in WWII

Delco-Remy WWII Aircraft Products

Delco-Remy WWII Marine

Equipment

Delco-Remy WWII Vehicle Products

Delco-Remy and LST-393

Delco-Remy WWII Kings Mills Plant

Delco-Remy WWII Antioch Foundry

Delco-Remy WWII

Stationary Engine Products

Delco-Remy WWII

Electrical Components for the Reo and Federal Truck, 20-Ton, 6x4

Delco-Remy Training Manuals for Aircraft Components

Delco-Remy in

World War Two

World War Two

Products and Product Applications

Components for Tanks

and Other Armored Vehicles

This page updated

12-4-2022.

Author's note: This page was added to the website in March

2016. The original information from 2016 was based on information noted in "Our War

Job," published by Delco-Remy in 1944. Since 2016, I have

learned considerably more from other research of other World War Two-era

companies about the armored vehicles in which Delco-Remy products were

utilized. Delco-Remy

equipment was used in a variety of armored vehicles that served with

several countries around the world. DDJ 5-10-2020

Delco-Remy Tank and Tracked Armored Vehicle Equipment

in World War Two: Sixteen models of

generators, 16 models of regulators, 16 models of starting motors, 6

models of ignition distributors, 8 models of ignition coils, 7 models of

storage batteries, and 3 electrical apparatus boxes for tanks and

armored vehicles.

Light Tanks: There were three types of light tanks produced

in the United States that had Delco-Remy electrical components in them.

These were the M3, M5, and M24. The M3 light tank began production

in 1940 and was used by American forces when the country entered the

war. These tanks saw action with not only the United States but

Commonwealth and Russian units. It served around the globe in

World War Two.

The M3 series light tanks were powered by

Continental W-670 radial engines. Delco-Remy was a non-exclusive

supplier of cranking motors for this engine. According to

technical manual "TM 9-1825, War Department Technical Manual, Ordnance

Maintenance, Electrical Equipment, (Delco-Remy)" dated 12 January 1944,

Delco-Remy provided six different model cranking motors for radial

engines. There is no specific mention of generators or voltage

regulators in the TM 9-1825. The W-670 used magnetos instead of a

distributor. Author's photo added 5-10-2020.

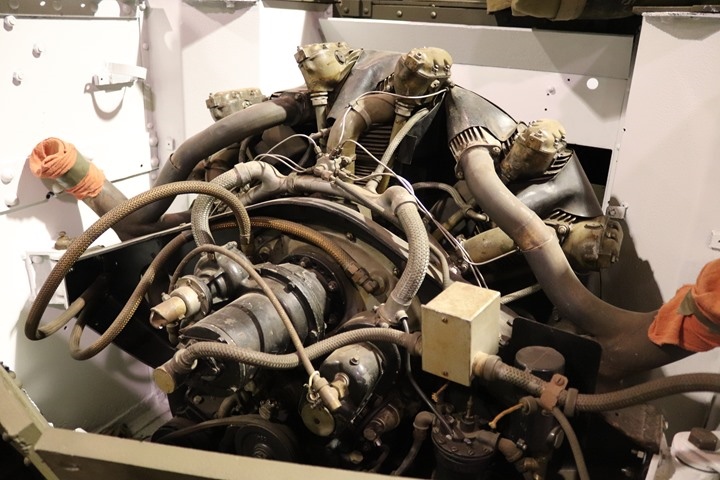

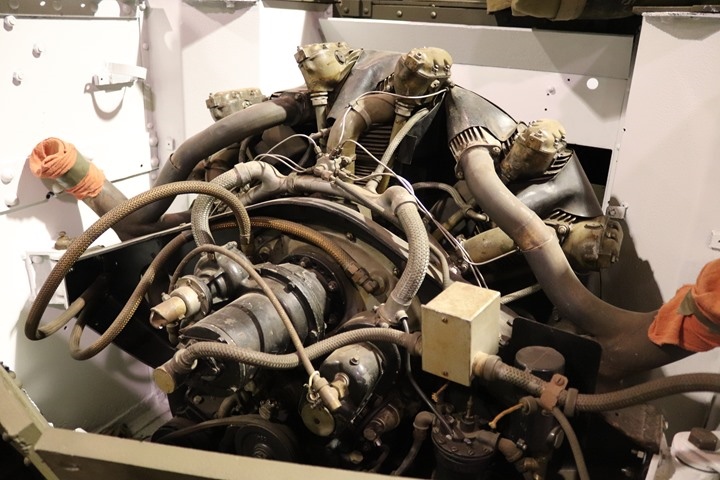

This is the top portion of the W-670 engine

in the rear of the M3 tank. Author's photo added 5-10-2020.

The M5 series was the next light tank produced.

Cadillac, Massey-Harris, and American Car and Foundry manufactured 8,884 M5 and

M5A1 Stuart tanks, built with two Cadillac 44T24 V-8 engines.

Delco-Remy furnished 17,768 sets of generators, starters, ignition

coils, ignition distributors, condensers, voltage regulators and

ignition switches for the tanks. Each 44T24 engine on the M5 and

M5A1 light tanks used the following Delco-Remy model numbers:

Ignition Coil-1115079, Condenser-1900272, Ignition

Distributor-1110609,10,11, Ignition Switch-19977756. Author's photo added 5-10-2020.

The last light tank produced was the M24

Chaffee which did not see action until 1944. Cadillac and Massey-Harris built 4,361 M24

Chaffee light tanks, also with the twin Cadillac 44T24 V-8 engines. All of the 8,722

sets of

electrical engine components were supplied by Delco-Remy. Each

44T24 engine on the M24 light tanks used the following Delco-Remy model

numbers. Author's photo.

Delco-Remy Components and Part Numbers in the M24 Chaffee

Light Tank

Added 6-8-2021. |

|

Component |

DR Part Number |

Number per Vehicle |

| Shielded

Ignition Coil |

1115282 |

2 |

|

Condenser |

1900272 |

2 |

|

Shielded Ignition Distributor |

1110611 |

2 |

|

Generator, 24 volts, 25 amps |

1117309 |

2 |

|

Current Regulator |

1903942 |

2 |

|

Generator Regulator |

1118501 |

2 |

|

Voltage Regulator |

1993932 |

2 |

|

Engine Starting Motor with Solenoid |

1108568 |

2 |

|

Starter Solenoid |

1118120 |

2 |

|

Engine Starter Relay |

1116840 |

2 |

|

Ignition Switch |

1997803 |

2 |

|

Starter Switch |

1996027 |

2 |

|

Stop Light Switch |

1197909 |

1 |

|

Electric Waterproof Horn |

1999883 |

1 |

|

Front Battery Terminal Block |

1904459 |

1 |

|

Rear Battery Terminal Block |

1904310 |

1 |

|

Radio Suppression Capacitor, Long Cable |

1906708 |

1 |

|

Radio Suppression Capacitor, Short Cable |

1906708 |

1 |

This is a Delco-Remy distributor cap for the

M24 Chaffee. This is D-R part number 1906532. The cap is an

assembly of a Bakelite inner core and an aluminum outer shield with

threads for securing the sparkplug wires. Photo added 11-16-2020.

This shows the Bakelite on the inside of the cap. Photo

added 11-16-2020.

Photo added 11-16-2020.

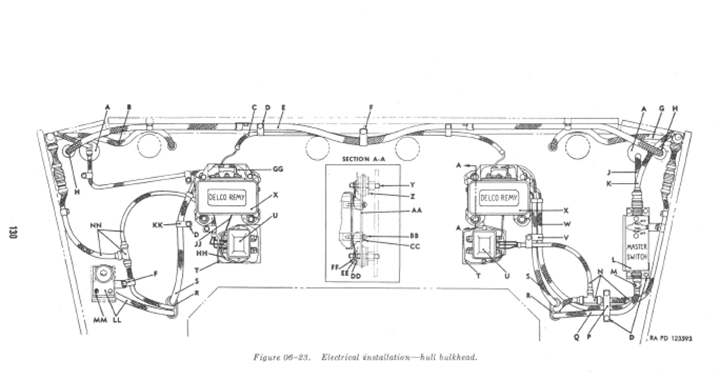

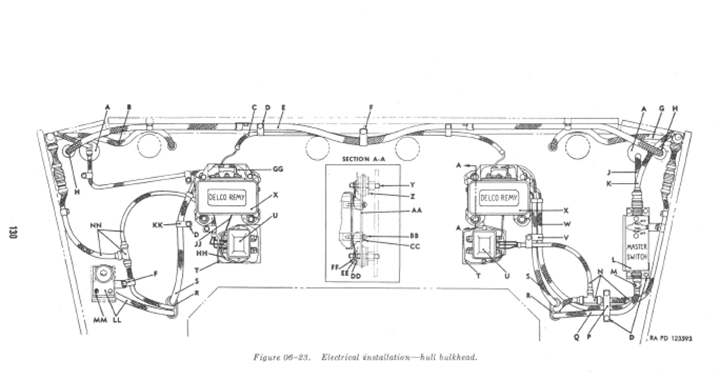

This image is from the M24 Ordnance Supply

Catalog and shows the rear bulkhead, or engine firewall, as viewed from

the interior of the tank. The drawing shows the Delco-Remy name

the regulators. This is very unusual for a military document to

show the supplier's name on a drawing. Image added 6-8-2021.

Medium Tanks: There were two

different types of American medium tanks built during World War Two.

The first was the M3 Lee/Grant medium tank, and the second the M4

Sherman. Both tanks used a variety of engines, some with

Delco-Remy as the exclusive supplier of engine electrical and other

components in the tank, and others, where Delco-Remy was one of several

suppliers for electrical components.

The M3A3 and M3A5 medium tanks were built

with two Detroit Diesel 6-71 diesel engines. Each engine had a

Delco-Remy cranking motor, generator, voltage regulator, and

supercharging blower. The M3A3 was provided to the British and

Russians through Lend-Lease, and consequently was used all over the

world during the war. This is M3A3 Lee Serial Number 1099 and was

manufactured by Baldwin Locomotive Works in May 1942. Baldwin

built all 322 M3A3s like this one with a welded hull. It also

built 591 M3A5s that had riveted hulls. Author's photo added

5-10-2020.

This is an M3 powered by a Continental

R-975 radial engine. Delco-Remy made six different model cranking

motors for use on armored vehicles with radial engines. A total of

4,924 were built by five different manufactures. This is one of

3,243 built by Chrysler. Note the riveted hull.

Author's photo added 5-10-2020.

-fortbenning-2018-107w-1.jpg)

This is an Alco-built M4 Sherman tank,

Serial Number 3949, built in April 1943. It is similar to many M4 medium

tanks built by several companies used by the American Army

during World War Two. Author's photo added 5-10-2020.

There were four versions of the Sherman tank

built during World War Two. The difference in them was the engine.

The engine of choice for the Sherman tank was the Continental R-975

radial engine which was used in the M4 and M4A1. The M4 and M4A1

served with the American Army for the duration of World War Two.

According to technical manual "TM 9-1825, War

Department Technical Manual, Ordnance Maintenance, Electrical Equipment,

(Delco-Remy)" dated 12 January 1944, Delco-Remy provided six different

model cranking motors for radial engines. There is no specific

mention of generators nor voltage regulators in the TM 9-1825. The

R-925 used magnetos instead of a distributor.

This M4A1 was built by Pressed Steel in July

1942. It had the same engine as the M4. The main difference

was that it had a cast rather than welded hull. Author's photo

added 5-10-2020.

Delco-Remy also supplied magneto switches

for the M4 and M4A1 Sherman tank and M18 tank destroyer. All three

armored vehicles were powered by the R-975 radial aircraft engine.

Photo added 11-16-2020.

Photo added 11-16-2020.

Photo added 11-16-2020.

Another version of the Sherman tank was the

M4A2, powered by two Detroit-Diesel 6-71 diesel engines, just like the

M3A3 and M3A5 Lee/Grant medium tank. Because this was a General

Motors-built engine, Delco-Remy was the exclusive supplier of electrical

components for the engines. General Motors always used parts made

by its component divisions on its engines and in its vehicles.

Below are several photos of cut-away of a M4A2 showing the Delco-Remy

components. The engines bays for the M3A3 and M3A5 would have

looked very similar.

The M4A2 was used in limited numbers by the

USMC; and was exported extensively to Great Britain and Russia through

Lend-Lease.

It may be hard to tell, but this is a

cut-away of a Sherman tank. This is a Fisher Body built M4A2 on

display at the Canadian War Museum in Ottawa, Ontario. It is

serial number 65001 and was built in March 1945 in Grand Blanc, MI.

Being a cut-away, this display allows one to see several

Delco-Remy-built components used on the Sherman tank. Author's

photo.

Looking inside, there is an orange box next to

the driver's seat. This is an apparatus box built by D-R.

Author's photo.

The second box to the right of the apparatus

box appears to the Delco-Remy voltage regulator. Author's photo.

Two Delco-Remy components can be seen

in the engine bay. Author's photo.

The first is the D-R cranking motor.

There were two D-R cranking motors for the Sherman tank model M4A2,

which was powered by two Detroit Diesel 6-71 engines. Author's photo.

This cut-away is unique in that it shows the supercharger blower.

Delco-Remy was a supplier of blowers. They were assembled in

Delco-Remy's Muncie battery

plant. Author's photo.

The table below summarizes the number of tanks

built during WWII with Detroit Diesel Division of GM engines, which

would have been equipped with Delco-Remy starters, DC generators,

voltage regulators, and blowers. The 21,520 diesel powered tanks

and tank destroyers were powered by 38,392 6-71 engines, each using a

Remy starter, generator, voltage regulator and blower. Delco-Remy cast

pistons for Detroit Diesel, which were used in the tank and tank destroyer

engines.

|

Detroit Diesel

Engine World War Two Tank Applications |

|

Armored Vehicle |

Number

built |

Type

Engine |

Engines per tank |

Total

Engines |

6-71

Engines per tank |

Total

6-71 Engines |

Total Blowers Required |

Comments |

|

British and Canadian Valentine |

3,981 |

6-71

|

1 |

3,981 |

1 |

3,981 |

3,981 |

|

|

British Valentine SP Anti-Tank with 17 pounder main gun |

665 |

6-71 |

1 |

665 |

1 |

665 |

665 |

|

| M3A3

and M3A5

Grant/Lee |

913 |

6046 |

1 |

913 |

2 |

1,826 |

1,826 |

The 6046 was two 6-71 engine blocks working together as one power

plant. |

| M4A2

Sherman Tank |

10,968 |

6046 |

1 |

10,968 |

2 |

21,936 |

21,936 |

This

was about 20% of the total M4 Sherman production in WWII.

The US Army preferred gasoline powered tanks, since

that was the fuel it normally used in its vehicles. The

Detroit Diesel powered M4A2 Shermans served either with the USMC,

which had access to US Navy diesel fuel, or were sent overseas as

part of Lend Lease. |

| M10

Tank Destroyer |

4,993 |

6046 |

1 |

4,993 |

2 |

9,986 |

9,986 |

The

M10 Tank Destroyer was a US Automobile Industry product being

built by the GM Fisher Body Division at Grand Blanc, MI. |

|

Totals |

21,520 |

|

|

21,520 |

|

38,392 |

38,392 |

This

does not include any spares. |

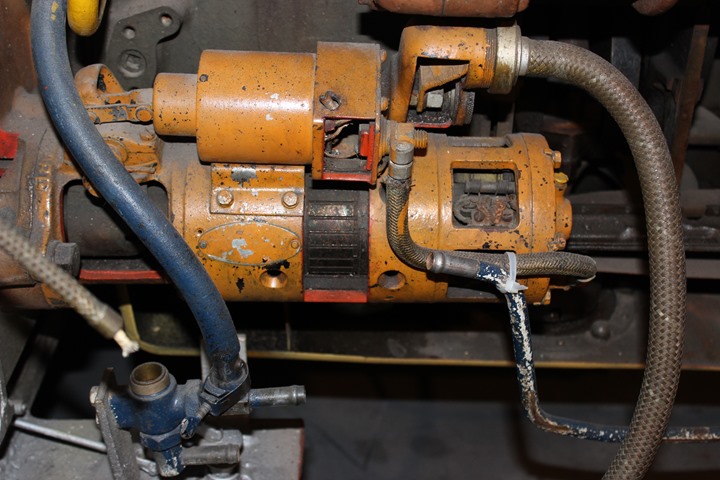

These 6046 tank engines are traveling down the Detroit Diesel assembly

line. One Delco-Remy starter and two DC generators can be seen on the first engine. The D-R tags can also be seen on

all three units. The blower can also be seen.

Six companies built 10,968 M4A2 Sherman

tanks, each powered by two Detroit Diesel 6-71 engines

married together and designated as the 6046 engine. Each 6046 had

two Delco-Remy starters, generators, and regulators which totaled 21,936 each. This photo was taken in Vancouver, BC and is courtesy of David Jackson, Jr.

Tank Destroyers:

The Fisher Body Tank Arsenal built 5,368 M10

Wolverine tank destroyers with the Detroit Diesel 6046 engine.

Delco-Remy supplied 10,736 starters, generators, and regulators for the

M10. Author's photo added 5-10-2020.

The M18 Hellcat tank destroyer was built by

the Buick Motor Division of General Motors and was powered by the

Continental R-975 engine. Delco-Remy was a non-exclusive supplier

for this engine. Being a General Motors-built product, other

Delco-Remy components could have been specified by Buick for this

vehicle. Author's photo added 5-10-2020.

Commonwealth-Built Tanks: The Valentine

infantry tank was built both in Canada and Great Britain. It was

powered by one Detroit-Diesel 6-71 diesel engine with Delco-Remy

electrical components.

This is one of 3,981 Valentine tanks built

in both Canada and Great Britain that used a Detroit Diesel 6-71 engine.

Author's photo added 5-10-2020.

Landing Vehicles, Tracked:

-107w-1.jpg)

The Landing Vehicle, Tracked(3) or LVT(3) was produced by Borg-Warner in

Kalamazoo, MI, and was powered by two Cadillac V-8 engines equipped with

Delco-Remy regulators, generators, ignition, and starters. Author's

photo.

-107w-2.jpg)

Looking into the LVT(3) from the open rear

of the vehicle, the Cadillac engine and Hydro-Matic transmission can be

seen in the opening on the starboard side sponson. Borg-Warner built 2,962 of the landing vehicles and

Delco-Remy supplied 5,924 engine electrical sets. Author's photo.

-right-107w-3.jpg)

Author's photo.

-left-107w-7.jpg)

The Delco-Remy distributor is visible.

Author's photo.

-left-107w-6.jpg)

A very rusted out Delco-Remy DC generator is

visible. Author's photo.

-left-107w-8.jpg)

Author's photo.

The LVT-4 used by both the USMC and the U.S.

Army had Delco-Remy components on it. The Marines used the LVT-4

for beach landings in the Pacific and the Army used them for river

crossings in Italy and Europe. Author's photo added 12-2-2020.

Self-Propelled Artillery:

Cadillac produced a 75mm howitzer

version of the M5 Stuart tank as the M8 75mm Gun Motor Carriage.

It had the same two Cadillac 44T24 V-8 engines with Delco-Remy components as

the M5 light tank. Cadillac built 1,778 M8s. Each 44T24

engine on the M8 used the following Delco-Remy model numbers:

Ignition Coil-1115079, Condenser-1900272, Ignition

Distributor-1110609,10,11, Ignition Switch-19977756.Author's photo added

5-10-2020.

This M7 Priest 105mm Gun Motor Carriage was one of

4,315 built that was powered by the Continental R-975 engine.

Delco-Remy was a non-exclusive supplier of cranking motors for the

R-975. Author's photo added 5-10-2020.

Armored Cars:

Chevrolet designed and built the Staghound

armored car used by the British and Canadians. Interestingly,

Chevrolet used two GMC 270 engines to power it with two sets of

Delco-Remy electrical components. Author's photo added 5-10-2020.

The Fox Armored Car was designated as a GM MK.1, but Chevrolet was the

Division that designed the chassis. Final assembly was done by GM

of Canada. The engine was a GMC 270 engine with Delco-Remy

cranking motor, distributor and coil, and D-C generator with voltage

regulator. Canadian Forces operated the Fox at Normandy.

Author's photo added 5-10-2020.

Half-Tracks:

There were 40,003 armored half-tracks built

during World War Two, powered by White 160AX engines. There were

fourteen different models of the half-track built with the 160AX engine

by Autocar, Diamond T, and White. Each engine had Delco-Remy

electrical components on it. The half-track was a

true utility vehicle and weapon used not only by the U.S. Army, but

Allied countries as well. It was used on a world-wide basis.

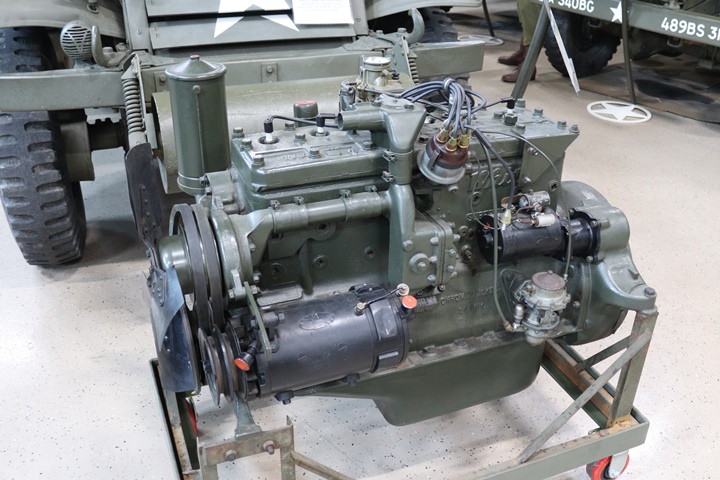

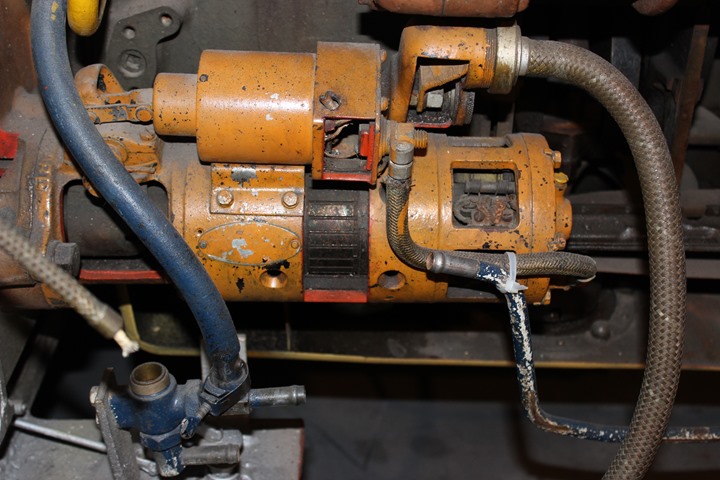

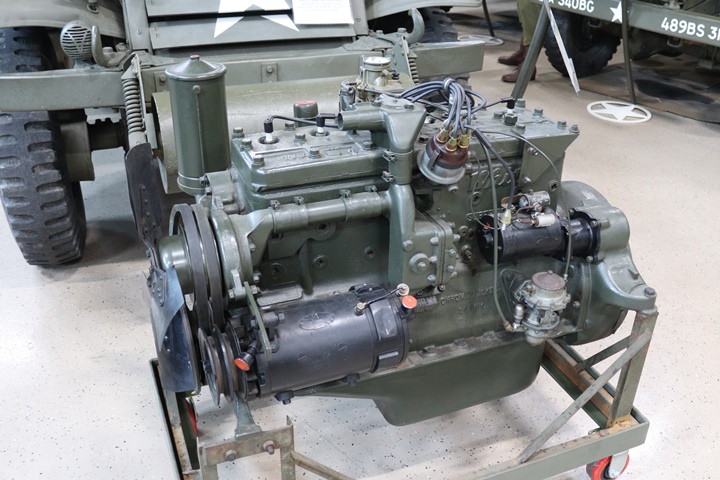

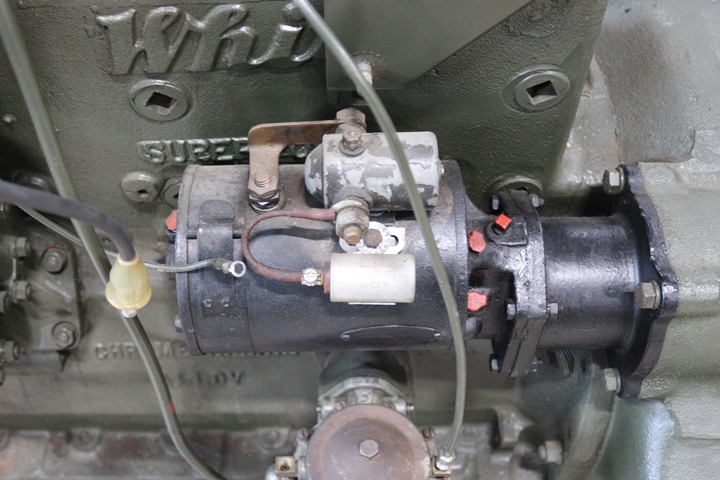

This White 160AX engine is on display at the

Veterans Memorial Museum in Oshkosh, WI. It has a Delco-Remy

cranking motor, DC generator, and distributor on it. Author's

photo added 12-4-2022.

Author's photo added 12-4-2022.

Author's photo added 12-4-2022.

A close-up photo of the DR tag on the DC

generator allows one to make out the name "Remy." Author's photo

added 12-4-2022.

Author's photo added 12-4-2022.

Author's photo added 12-4-2022.

The Diamond T M3A1 shown here is a

representative sample of all the various types. Author's photo

added 5-10-2020.

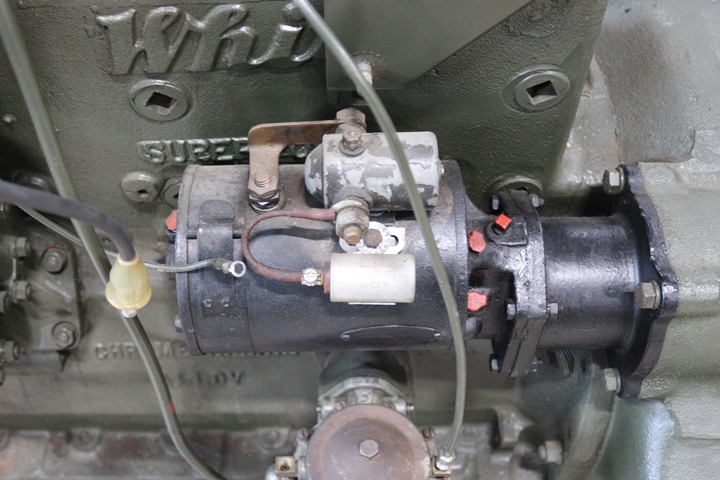

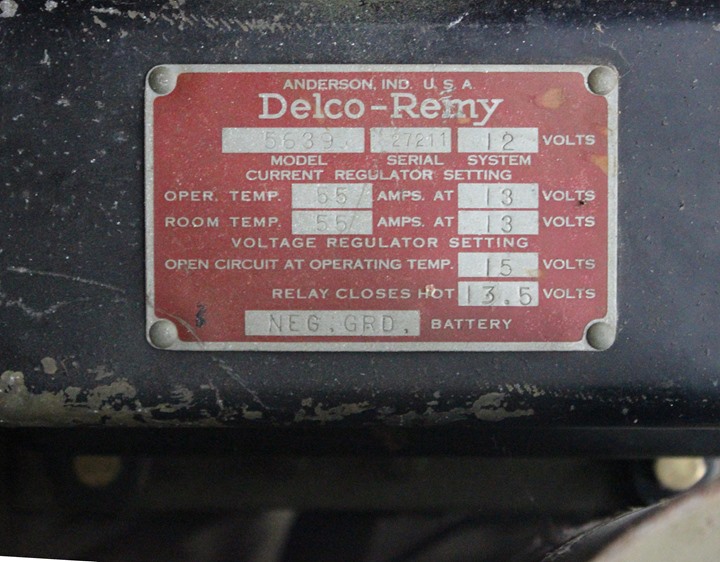

A Delco-Remy data plate is on the voltage

regulator located on the fire wall. A Delco-Remy distributor,

ignition coil, and cranking motor are located on the White 160AX engine.

Author's photo added 5-10-2020.

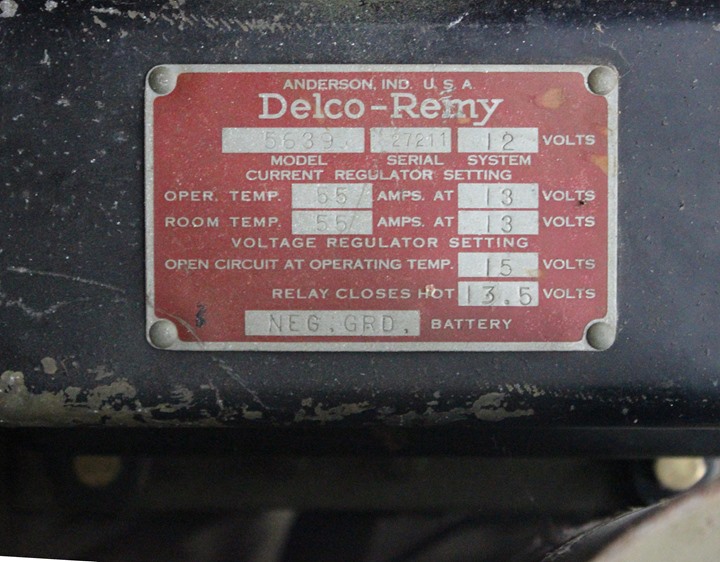

The voltage regulator is model 5639 and

serial number 27211. Author's photo added 5-10-2020.

This White M2 half-track is awaiting

restoration at the Indiana Military Museum in Vincennes, IN.

Author's photo added 5-10-2020.

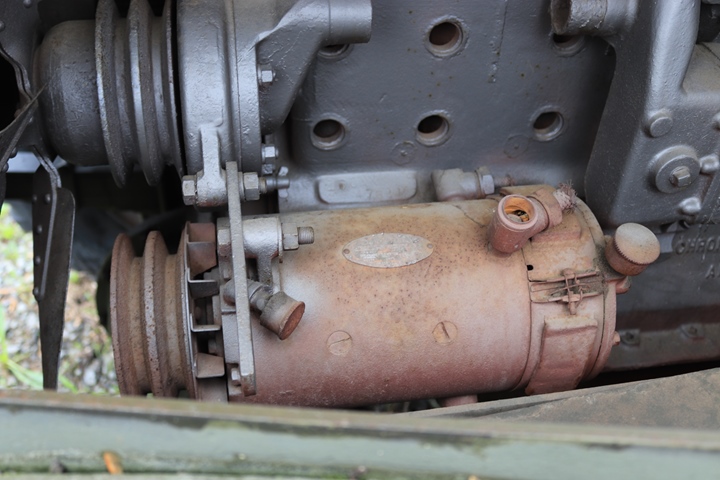

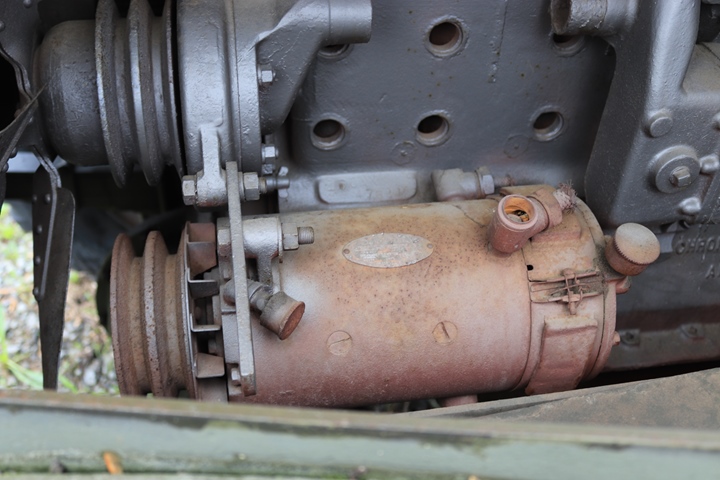

With the hood off, the Delco-Remy generator

can be seen. These components are 170 miles from Anderson, IN

where they were built during World War Two. Author's photo added

5-10-2020.

Author's photo added 5-10-2020.

The D-R tag is worn from almost 80 years of

wear and tear, but the name Delco-Remy is just visible. Author's

photo added 5-10-2020.

This White M16 half-track was photographed

in the motor pool of the New Jersey National Guard Museum Annex in

Lawrenceville, NJ. Author's photo added 6-5-2020.

With the hood open, I was able to photograph

the Delco-Remy DC generator. Author's photo added 6-5-2020.

Author's photo added 6-5-2020.

This Diamond T M3A1 half-track was

photographed at Fort Benning, GA. Author's photo added 3-22-2021.

Delco-Remy supplied the controls for opening

and closing the air vents on the World War Two half-tracks. The

far left pull knob on the instrument panel is DR-1990554 and the control

on the far right is DR-1990554. These are both known as ventilator

controls. The left ventilator control, DR-1990554 is 35 inches in

length and DR-1990553 is 31.5 inches long. Delco-Remy supplied

53,625 of each for all of the half-tracks built. Author's photo

added 3-22-2021.

International Harvester also made half-tracks during World War Two, but

they were slightly different than the ones made by Autocar, Diamond T,

and White. This International M5 half-track is one of 4,625 built.

In total, International Harvester built 16,622 half-tracks in six

different models. One of the differences in the International

half-tracks was its engine, which was a IH Red Diamond rather than the

White 160AX. Both half-track engines had Delco-Remy electrical

systems. International half-tracks were equipped with Delco-Remy 1117308 D-C Generators and 1110161 distributors, along with

other electrical components. Author's photo added 12-2-2020.

Another model half-track International built

was the M9, of which 2,606 were built. This one was then converted

into an M9A1 Author's photo added 12-2-2020.

|

-fortbenning-2018-107w-1.jpg)

-107w-1.jpg)

-107w-2.jpg)

-right-107w-3.jpg)

-left-107w-7.jpg)

-left-107w-6.jpg)

-left-107w-8.jpg)